Price 4700 आईएनआर/ टुकड़ा

Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- भुगतान की शर्तें

- आपूर्ति की क्षमता

- प्रति सप्ताह

- डिलीवरी का समय

- दिन

- नमूना उपलब्ध

- Yes

- नमूना नीति

- मुख्य घरेलू बाज़ार

About

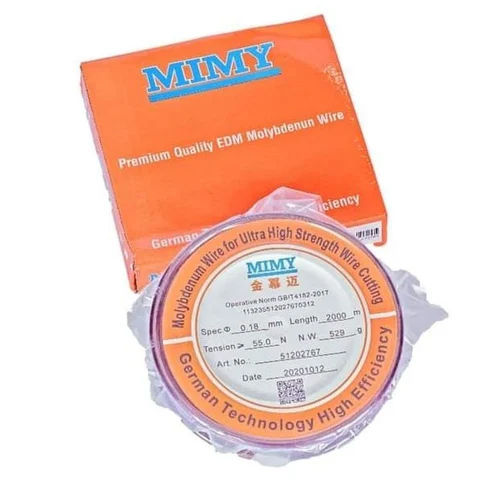

EDM Wire Cut Molybdenum Wire (0.18 mm) refers to a specific type of wire used in Electrical Discharge Machining (EDM), a manufacturing process that utilizes electrical discharges to cut and shape materials. Molybdenum wire, in this case, has excellent properties that make it suitable for precision cutting in complex, high-accuracy jobs.

Key Details of EDM Wire Cut Molybdenum Wire (0.18 mm):

- Diameter: 0.18 mm

- Material: Molybdenum

- Application: Primarily used in the EDM Wire Cut process (also known as Wire EDM), where the wire acts as an electrode that cuts through conductive materials without physical contact, using rapid, controlled electrical discharges.

Characteristics of Molybdenum Wire for EDM:

- High Melting Point: Molybdenum has a very high melting point (3,180C or 5,756F), making it highly resistant to wear and damage from the intense heat generated during EDM.

- Electrical Conductivity: The wire needs to conduct electricity efficiently to allow the EDM process to work. Molybdenum has excellent conductivity, making it ideal for wire EDM.

- Stability: The wire maintains its mechanical properties and dimensional stability during the cutting process, ensuring precision and consistency.

- Wear Resistance: Molybdenum wire has high resistance to wear, which is important for maintaining cutting accuracy over long periods.

- Thin Diameter: The thin diameter (0.18 mm) allows for fine, precise cuts, enabling the production of intricate shapes and small features.

- Corrosion Resistance: Molybdenum resists oxidation and corrosion, which is crucial in the EDM process, especially in high-temperature or aqueous environments.

Applications of EDM Molybdenum Wire (0.18 mm):

- Precision Machining: EDM with molybdenum wire is commonly used for high-precision cutting of hard materials like tool steel, carbide, and other alloys.

- Aerospace and Automotive: Used for cutting complex geometries in aerospace components, including turbines, blades, and molds.

- Medical Device Manufacturing: For creating intricate, small parts, such as surgical tools or implants.

- Molds and Dies: Used for cutting and shaping molds, dies, and other components that require fine features.

- Electronics Manufacturing: Molybdenum wire is often used in the production of electronic components and parts that require high precision.

Why Molybdenum for EDM?

- Precision: Molybdenum wire helps achieve very fine and accurate cuts, with minimal heat-affected zones.

- Durability: The material™s high resistance to thermal wear extends the life of the wire, reducing downtime and increasing productivity in high-precision applications.

- Cost-Effectiveness: Although molybdenum wire can be more expensive than some other materials, its long lifespan and high performance in demanding applications can justify the investment.

Conclusion:

Molybdenum wire of 0.18 mm diameter is a high-performance material used for Wire EDM applications, where precision and durability are essential. Its properties make it a go-to option for industries requiring intricate cuts in tough, conductive materials.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in मोलिब्डेनम तार Category

मोलिब्डेनम तारों का छिड़काव करें

प्रॉडक्ट टाइप : मोलिब्डेनम स्प्रे तार

वारंटी : हाँ

मटेरियल : मोलिब्डेनम

फंक्शन : मोलिब्डेनम भट्टी के उच्च तापमान वाले क्षेत्र में उपयोग किया जाता है

मूल्य की इकाई : किलोग्राम/किलोग्राम

न्यूनतम आदेश मात्रा : 1

मिमी प्रीमियम क्वालिटी ईडीएम मोलिब्डेनम वायर

प्रॉडक्ट टाइप : मिमी प्रीमियम गुणवत्ता ईडीएम मोलिब्डेनम तार

वारंटी : हाँ

मटेरियल : मोलिब्डेनम

फंक्शन : टुकड़ा करने, काटने के लिए उपयुक्त

मूल्य की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 100

3.17 मिमी और 2.31 मिमी मोलिब्डेनम स्प्रे वायर

प्रॉडक्ट टाइप : मोलिब्डेनम स्प्रे तार

वारंटी : हाँ

मटेरियल : मोलिब्डेनम तार 3.17 मिमी

फंक्शन : ऑटोमोटिव घटकों का छिड़काव करें

मूल्य की इकाई : किलोग्राम/किलोग्राम

न्यूनतम आदेश मात्रा : 1

JDC EDM मोलिब्डेनम वायर

प्रॉडक्ट टाइप : जेडीसी ईडीएम मोलिब्डेनम वायर

वारंटी : हाँ

मटेरियल : मोलिब्डेनम

फंक्शन : टुकड़ा करने, काटने के लिए उपयुक्त

मूल्य की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 100

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese