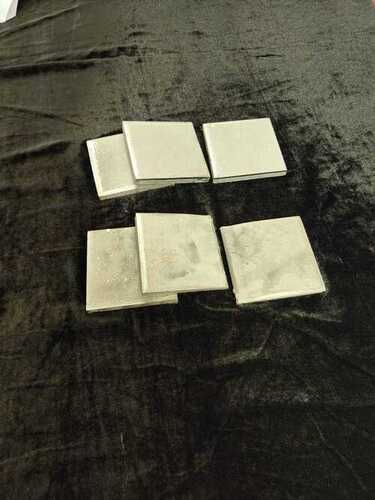

Nickel Briquette

Nickel Briquette Specification

- Strength

- High tensile

- Hardness

- 75 HRB

- Purity

- 99.8% min

- Product Type

- Briquette

- Material

- Nickel

- Alloy

- Pure Nickel

- Shape

- Briquette

- Moisture

- <0.1%

- Chemical Composition

- Ni: 99.8% min, C: <0.05%, Fe: <0.2%, S: <0.02%

- Application

- Electroplating, Alloy Production, Chemical Synthesis

- Dimension (L*W*H)

- 40x20x10 mm (Approx)

- Color

- Silver Grey

- HS Code

- 75021000

- Impurities

- Trace levels of Cu, Zn, Pb <0.01%

- Surface finish

- Matte

- Storage Condition

- Dry, cool place

- Packing type

- 25 kg bags / drums

- Density

- 8.90 g/cm³

- CAS No.

- 7440-02-0

- Melting Point

- 1455°C

Nickel Briquette Trade Information

- Minimum Order Quantity

- 10 Kilogram

- FOB Port

- JNPT

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union

- Supply Ability

- 5000 Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka

About Nickel Briquette

Overview

Nickel Briquettes: Nickel briquettes are compacted forms of nickel, often produced by compressing nickel powder into solid, manageable blocks or shapes. They are designed for ease of handling, storage, and transportation.

Superior Purity and Strength

Nickel Briquettes boast an impressive purity level of at least 99.8% Ni, ensuring optimal performance for demanding industrial applications. Their high tensile strength and consistent hardness offer enhanced durability, making them ideal for electroplating, alloy manufacturing, and chemical synthesis processes. Careful chemical composition and low trace impurities provide reliability in end-use sectors.

Packaging and Storage

Nickel Briquettes are available in 25 kg bags or drums, suitable for a variety of suppliers, exporters, and manufacturers. The recommended storage environment is a dry and cool place to preserve the materials integrity. Proper packaging ensures easy transportation and handling, minimizing oxidation risk and maintaining product quality during transit.

FAQs of Nickel Briquette:

Q: How should Nickel Briquettes be stored to maintain quality?

A: Nickel Briquettes should be stored in a dry and cool location to prevent moisture absorption and preserve their matte finish and high purity. Avoid exposing them to humid conditions to minimize oxidation and ensure longevity.Q: What are the main industrial applications for Nickel Briquettes?

A: Nickel Briquettes are primarily used in electroplating, alloy production, and chemical synthesis. Their high purity and consistent physical properties make them suitable for creating advanced nickel-based alloys and coatings.Q: When is it necessary to choose Nickel Briquettes with high purity and minimal impurities?

A: High-purity Nickel Briquettes are essential when trace elements must be avoided, such as in electronics, specialized alloys, or precision electroplating, ensuring consistent chemical properties in the end product.Q: Where can Nickel Briquettes be supplied, and who are the typical distributors?

A: Nickel Briquettes are distributed worldwide by various dealers, manufacturers, exporters, suppliers, importers, traders, wholesalers, and retailers, catering to industries requiring reliable nickel sources.Q: What process is used to produce Nickel Briquettes with 99.8% purity?

A: Nickel Briquettes are manufactured through refining and compacting processes that remove impurities and moisture, resulting in a dense product with high purity, minimal trace metals, and a reliable chemical composition.Q: How are Nickel Briquettes typically packaged for shipment?

A: Nickel Briquettes are commonly packed in 25 kg bags or drums, ensuring easy handling and secure transportation, with clear labeling for HS Code (75021000) and CAS Number (7440-02-0) compliance.Q: What benefits do Nickel Briquettes offer in alloy manufacturing?

A: Nickel Briquettes provide consistent composition and high tensile strength, supporting the production of robust alloys with precise chemical properties, reducing contamination risks and enhancing end-product quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Nickal Category

JAPAN Nickel Plate

Price 1390 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Shape : Sheet

Dimension (L*W*H) : 4*4*4*4 Inch (in)

Purity : 99.97%

Product Type : Metal

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese