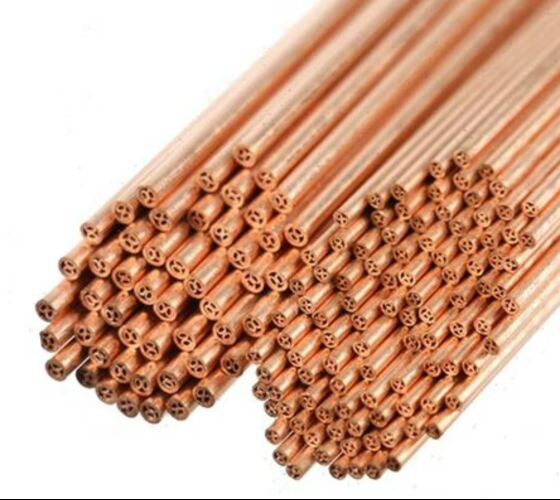

Multi hole electrodes tube

Price 70 INR/ Number

Multi hole electrodes tube Specification

- Product Type

- Copper Tubes

- Material

- Copper

- Shape

- Round

- Technique

- Extruded and Drawn

- Surface Treatment

- Polished / Annealed

- Standard

- ASTM B280 / EN 12735-1

- Outer Diameter

- Available from 5mm to 100mm Millimeter (mm)

- Length

- Custom Length / Standard 3m, 6m Meter (m)

- Wall Thickness

- 0.5mm to 5mm Millimeter (mm)

- Tensile Strength

- >200 MPa Megapascals (MPa )

- Grade

- C12200 (or as specified)

- Size

- Multi-hole, custom configurations

- Color

- Copper/Bright

- Conductivity

- 97% IACS @ 20C

- Operating Temperature

- Up to 400C

- Hardness

- Soft/Annealed (HB 65-90)

- Fabrication

- Can be bent and flared

- Application

- EDM, electrical discharge machining, heat exchangers, power transmission

- Packaging

- Export worthy bundles, wooden boxes

- Ends

- Plain or deburred

- Corrosion Resistance

- Excellent, suitable for harsh environments

- Density

- 8.89 g/cm

- Number of Holes

- Typically 3, 4, 5, 6, 7 or customized

Multi hole electrodes tube Trade Information

- Minimum Order Quantity

- 100 Number

- Supply Ability

- 1000 Per Day

- Delivery Time

- 2 Days

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Main Domestic Market

- All India

About Multi hole electrodes tube

You said:

ChatGPT said:

Brass Multi-Electrodes are specialized electrodes made from brass that are used in the Electrical Discharge Machining (EDM) process, especially in Sinker EDM and Wire EDM. These electrodes feature multiple electrodes or multiple segments in a single assembly, which can have a significant impact on machining precision, efficiency, and cooling.

Key Features of Brass Multi-Electrodes:

-

Material:

- Brass is a commonly used material for EDM electrodes due to its excellent electrical conductivity, thermal conductivity, and machinability. Its a blend of copper and zinc, providing the benefits of coppers high conductivity and zincs added strength.

- Brass is often chosen for its affordability compared to other materials like copper or copper-tungsten, and it provides good performance for precision machining.

-

Multi-Electrode Design:

- A multi-electrode setup means that there are several electrode segments or configurations working together to achieve a particular machining task. In EDM, this could refer to an electrode with multiple segments or branches, each potentially contributing to a specific part of the machining process.

- In some designs, multiple brass electrodes are placed in a pattern or arrangement to simultaneously cut different sections of the workpiece. This can increase the efficiency of the EDM process, especially for more complex parts that need uniform machining.

-

Cooling and Flushing:

- Brass electrodes, especially when used in multi-electrode configurations, can benefit from designs that allow for better dielectric fluid flow. The fluid is essential for cooling the electrode and workpiece during the EDM process, and multi-electrode designs can improve the flushing efficiency, removing debris and enhancing machining accuracy.

-

Precision and Stability:

- Brass provides good stability and consistent electrical performance, which is key when precise and high-quality cuts are required.

- The multi-electrode setup can improve the surface finish of the workpiece and reduce the wear on individual electrodes, as the workload is distributed across several electrodes.

Premium Copper Multi-Hole Tubes for Precision Applications

These multi-hole electrode tubes are meticulously manufactured using advanced extrusion and drawing techniques. They deliver outstanding electrical conductivity, making them the top choice for precise EDM operations and efficient heat exchangers. The polished, annealed finish and superior copper grade (C12200) ensure reliability and durability even in the most demanding settings. With customizable options for size, diameter, wall thickness, and length, these tubes meet a wide range of industry specifications, supporting flexible integration and excellent performance.

Engineered for Durability and Harsh Conditions

Constructed from high-grade copper, the multi-hole tubes resist corrosion and oxidation even in challenging and aggressive environments. Their soft/annealed finish allows for easy fabircationbending, flaring, and shaping to exact requirements. Packaged securely in export-worthy bundles or wooden boxes, every tube arrives in perfect condition, ready for immediate use in power, manufacturing, or industrial systems.

FAQs of Multi hole electrodes tube:

Q: How are multi-hole electrode tubes used in electrical discharge machining (EDM)?

A: Multi-hole electrode tubes serve as precision-guided electrodes in EDM processes, allowing efficient cooling and debris removal during machining. Their multiple channels permit simultaneous flushing, enhancing cutting accuracy and tool longevity.Q: What benefits do multi-hole electrode tubes offer in heat exchanger applications?

A: In heat exchangers, the multiple holes increase the surface area available for heat transfer, while the coppers high conductivity ensures rapid energy exchange. This boosts the overall efficiency and performance of cooling or heating systems.Q: Where are these copper multi-hole tubes typically installed or utilized?

A: These tubes are widely used in industrial EDM equipment, power transmission components, advanced manufacturing facilities, refineries, and HVAC heat exchangers, especially in environments that demand excellent electrical and thermal conduction.Q: What is the process for customizing the diameter, length, and hole configuration?

A: Customers can specify their requirements for inside and outer diameter, hole number, length, and configuration when placing an order. The tubes are then extruded and drawn to precise standards using advanced manufacturing methods, ensuring adherence to ASTM B280 or EN 12735-1.Q: When should you choose soft/annealed tubes over hard temper tubes?

A: Soft/annealed tubes are ideal when you need to perform additional fabrications such as bending, flaring, or shaping since they are more malleable. These properties make them suitable for customized installations or intricate assemblies.Q: How does the corrosion resistance of these tubes benefit harsh environments?

A: The tubes excellent corrosion resistance enables them to withstand harsh and chemically aggressive environments without degrading, ensuring a longer service life and minimizing maintenance or replacement needs.Q: What makes these copper multi-hole tubes suitable for export and international distribution?

A: The tubes are rigorously inspected, meet global quality standards, and are packaged securely in export-worthy bundles or wooden boxes. This ensures safe transportation and delivery, making them reliable for global supply chains.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Copper Electrode Tube Category

Multi hole copper electrodes tube

Price 30 INR / Number

Minimum Order Quantity : 1 Number

Shape : Other, Round, MultiChannel

Size : Customized (variety of sizes available depending on application)

Color : Reddish Brown (Copper Natural)

Product Type : Other, Multi Hole Copper Electrodes Tube

Red Copper Pipe

Price 12 INR / Piece

Minimum Order Quantity : 100 Pieces

Shape : Round

Size : 400500mm

Color : Red

Product Type : Copper Tubes

Edm Brass Tubes

Price 10.0 INR / Piece

Minimum Order Quantity : 100

Shape : Round

Size : 400500mm

Color : Golden

Product Type : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese