FANUC EDM FILTER

Price 7000 INR/ Number

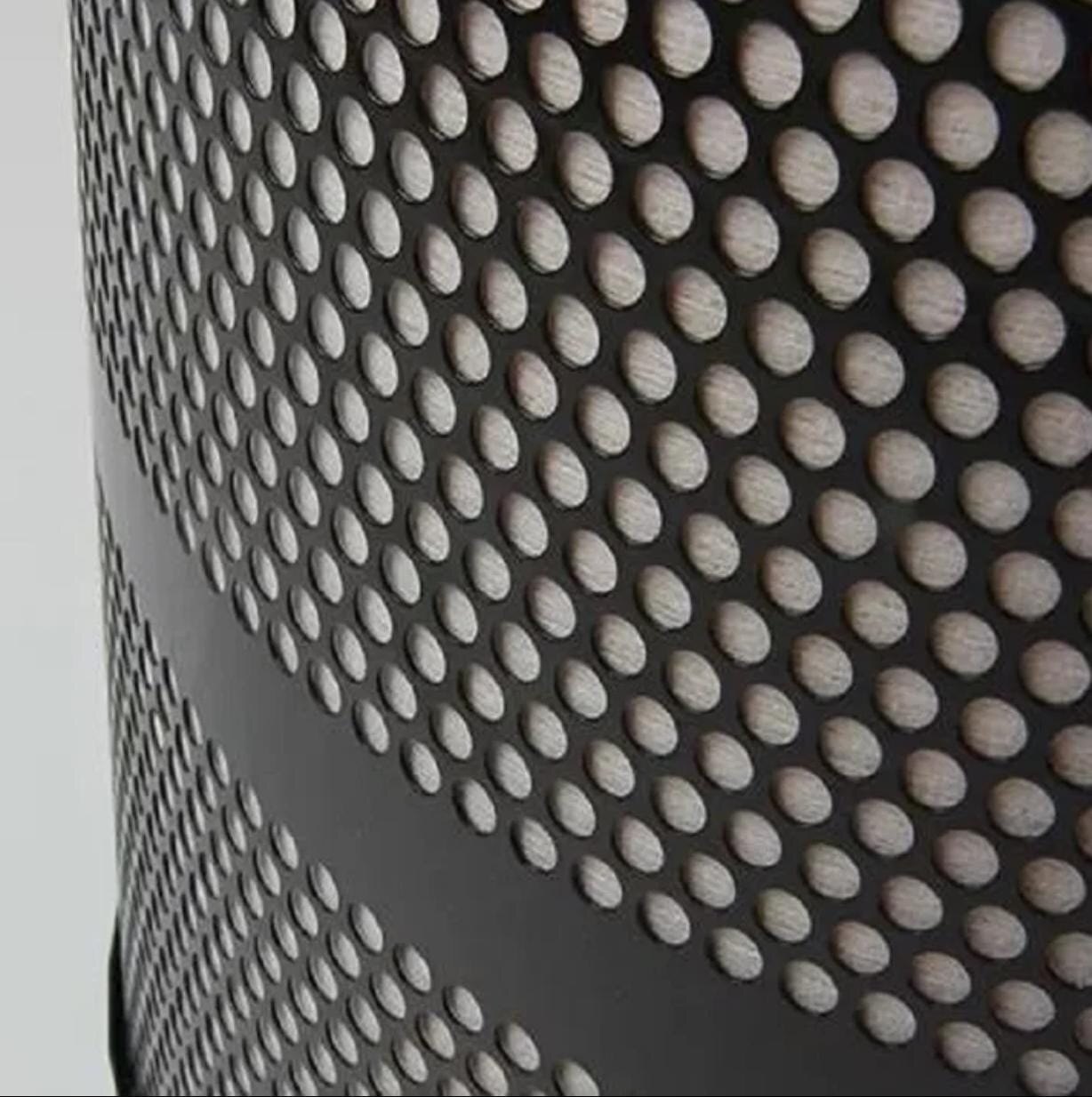

FANUC EDM FILTER Specification

- OEM/ODM Service

- Available

- Core Material

- Galvanized steel

- Colour

- White

- Weight

- 2.8 kg

- Application

- Electrical Discharge Machine (EDM)

- Made in

- India

- Packaging Type

- Corrugated Box

- Filtration Efficiency

- High efficiency for EDM machining fluids

- Maximum Pressure

- 7 bar

- Replacement Frequency

- Depends on operation hours and condition

- Product Name

- FANUC EDM Filter

- Filter Type

- Cartridge / Replacement Filter

- End Cap Material

- Plastic / Polypropylene

- Inner Support

- Polypropylene core

- Condition

- New

- Filter Media

- High performance cellulose + synthetic fibers

- Compatible Brand/Model

- FANUC EDM Machines

FANUC EDM FILTER Trade Information

- Minimum Order Quantity

- 2 Number

- Delivery Time

- 7 Days

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About FANUC EDM FILTER

EDM (Electrical Discharge Machining) is a manufacturing process that removes material from a workpiece using electrical discharges (sparks). To ensure optimal performance and longevity of the EDM machine, filters are essential.

What Do EDM Filters Do?

- Remove contaminants: They capture and hold particles, debris, and other impurities from the dielectric fluid used in the EDM process.

- Maintain fluid purity: By preventing contamination, they help maintain the dielectric's cooling and insulating properties.

- Protect machine components: Clean dielectric fluid reduces wear and tear on the EDM machine's components, extending their lifespan.

- Improve machining accuracy: Contaminants can interfere with the EDM process, leading to inaccuracies. Filters help prevent this.

Types of EDM Filters

- Wire EDM filters: Specifically designed for wire EDM machines, these filters remove fine particles that can affect wire tension and cutting accuracy.

- Sinker EDM filters: Used in sinker EDM machines, these filters capture larger debris and impurities that can impact electrode erosion and workpiece finish.

- EDM drill filters: Essential for EDM drilling, these filters remove particles that can clog the drill and reduce drilling efficiency.

Filter Media

EDM filters use various filter media, including:

- Paper: Offers good filtration efficiency but can be prone to clogging.

- Synthetic fiber: Provides higher dirt-holding capacity and longer life compared to paper.

- Metal mesh: Used for coarser filtration, often as a pre-filter to protect finer filters.

Importance of Filter Maintenance

Regular filter inspection and replacement are crucial for optimal EDM performance. A clogged filter can lead to decreased efficiency, reduced machining accuracy, and even machine damage.

What is an EDM filter and why is it important?

EDM filters are crucial components in Electrical Discharge Machining (EDM) processes. They remove impurities and contaminants from the dielectric fluid used to facilitate the machining process. This is essential for:

- Maintaining fluid purity: Impurities can degrade fluid quality, affecting machining efficiency and part quality.

- Preventing machine damage: Contaminants can clog nozzles, damage electrodes, and shorten machine lifespan.

- Improving part quality: Clean fluid results in better surface finish and dimensional accuracy.

How do EDM filters work?

EDM filters typically employ a combination of mechanical and magnetic filtration methods.

- Mechanical filtration: Physical barriers like mesh or paper trap larger particles.

- Magnetic filtration: Magnets attract and hold ferrous contaminants, preventing them from circulating in the fluid.

What are the different types of EDM filters?

There are primarily two types:

- Conventional filters: Fluid flows from the outside to the inside of the filter.

- Reverse flow filters: Fluid flows from the inside to the outside of the filter.

The choice of filter depends on the specific EDM machine and its requirements.

How often should EDM filters be replaced or cleaned?

The frequency of filter replacement or cleaning depends on factors like:

- Fluid type and condition

- Machining process intensity

- Filter type and capacity

- Manufacturer recommendations

Regular inspection and maintenance are crucial to ensure optimal filter performance.

What are the signs of a clogged or ineffective EDM filter?

Signs of a clogged or ineffective filter include:

- Increased sparking or arcing

- Deteriorating part quality

- Reduced machining efficiency

- Increased fluid consumption

- Pressure build-up in the fluid system

How can I improve the lifespan of my EDM filter?

To extend filter life:

- Use high-quality dielectric fluid

- Regularly inspect and clean the filter

- Adhere to recommended filter replacement intervals

- Maintain proper fluid levels

- Avoid excessive machine operation without filtration

What are the benefits of using a high-quality EDM filter?

A high-quality EDM filter offers:

- Improved part quality and finish

- Increased machine uptime and productivity

- Extended dielectric fluid life

- Reduced maintenance costs

- Enhanced overall machining efficiency

Can I use a generic filter for my EDM machine?

It's generally recommended to use filters specifically designed for EDM applications. Generic filters might not provide the necessary filtration level or durability.

How does magnetic filtration help in EDM?

Magnetic filtration is highly effective in removing ferrous particles, which are a common contaminant in EDM processes. By capturing these particles, magnetic filters significantly reduce secondary sparking, improve part quality, and extend fluid life.

Superior Filtration Efficiency

Fitted with high-quality cellulose and synthetic fiber media, the FANUC EDM Filter ensures excellent removal of particulates, maintaining pure fluids critical for precision EDM machining. This leads to improved machining accuracy and reduced maintenance for machines.

Rugged Construction for Longevity

The filter incorporates a galvanized steel core and robust polypropylene components, offering resistance to high pressures up to 7 bar and physical stress during operation. Each filter undergoes strict quality controls in India to maximize durability and reliability in demanding environments.

FAQ's of FANUC EDM FILTER:

Q: How do I install the FANUC EDM Filter in my FANUC Electrical Discharge Machine?

A: Installation involves replacing the existing filter cartridge with the new FANUC EDM Filter by following your machine's filter replacement guidelines. Ensure the filter fits securely in the housing, with end caps properly aligned for optimal performance.Q: What is the recommended replacement frequency for the FANUC EDM Filter?

A: Filter replacement depends on operation hours and the condition of your machining fluids. It's best to check filter efficiency periodically and replace when flow rates decrease or contamination increases, typically after heavy or prolonged EDM use.Q: Where is the FANUC EDM Filter manufactured and supplied from?

A: This filter is made in India and is available through a broad network of dealers, distributors, exporters, and other suppliers across India and internationally.Q: What process does the FANUC EDM Filter use to ensure high-efficiency filtration?

A: The filter utilizes a specialized blend of high-performance cellulose and synthetic fibers to capture and remove fine particles from EDM fluids, supporting high-efficiency filtration suitable for advanced EDM machining operations.Q: What are the main benefits of using the FANUC EDM Filter in my EDM machine?

A: Using this filter improves machining precision, extends the lifespan of EDM fluids, protects sensitive machine components, and reduces the frequency of machine downtime and maintenance efforts.Q: Can the FANUC EDM Filter be customized for OEM or ODM requirements?

A: Yes, OEM/ODM services are available, allowing customization of the filter to meet specific operational or branding needs for dealers, fabricators, and EDM equipment manufacturers.Q: What is the packaging type and weight of the FANUC EDM Filter?

A: The filter is packaged securely in a corrugated box and weighs 2.8 kg, ensuring safe transport and handling from supplier to end-user.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese